In another post on this community, partially just trying to generate a conversation, i asked about adaptable coil-on-plug modules. A couple folks were helpful, but it’s still thin on the ground here, that’s cool, it’s all new, etc. Here it is: https://lemmy.world/post/1263808 (not much).

But I’m serious about designing and building a new ignition system for this ancient, forgotten engine that I’m kinda expert on by now (that expertise plus five bucks buys me coffee at starbucks). I’ve got two cars with this engine now, it’s just barely tenable to drive now, parts are extremely scarce (eg. timing chain setups).

Anyway this engine, the Rambler 195.6 cubic inch inline 6, has roots back to the 1940’s, AMC slapped a shitty OHV head on the old flathead engine, introduced a number of reliability problems, then solved those just as they introduced the brand new design engine, the 199/232/258.

It’s got a once-conventional distributor, contact points and coil ignition. There’s a Pertronix in there now. It works fine, but I hate them – the distributor has to crank two rotations before it fires the coil, so the engine cranks for over a second each time, instead of firing right up on the first contact-point opening. I WANT THAT BACK.

So I’m gonna make new electronic guts for the distrib, drive some form of coil-on-plug, and do software spark control in the computer I’ve got already running the electronic carburetor.

ITT is chat about research, photos, etc. I’ll make a web page for the project like I usually do. My Rambler Lore website is https://www.ramblerlore.com/index.html

Here’s the page on this engine: https://www.ramblerlore.com/AMC/195.6ohv/index.html

Last post today: the distributor (no photos yet) is a typical old Delco Remy, they’re OK, but all of them are worn out after 60 years, shafts wobble, etc, and new ones don’t exist and no one rebuilds them any more (I do my own).

The plan is to replace the distributor guys with an optical coder that gives absolute position so the first cylinder fire position reached actually generates a spark – [EDIT:] 60 degrees of crankshaft rotation, not 720 etc. Pertronix II needs a full rev to determine angle and another I think to work out coil dwell.

I use MegaJolt/e with EDIS-6 on one of these engines in my sports car, but that stuff is old now, I dislike the single-source Megajolt now, 10 years later. With COP it;s just some logic drivers, sensors, and a spark map. I’m running two fuel maps now for the carb (AFR and enleanment feedback) so spark will be easy.

Here’s a distributor stripped to the housing, shaft, and drive gear. The mechanical advance was stripped out of this one, but for fail-back purposes the one that goes in the car will have the advance junk retained, just pinned to disable, so in theory the contact points could go back in.

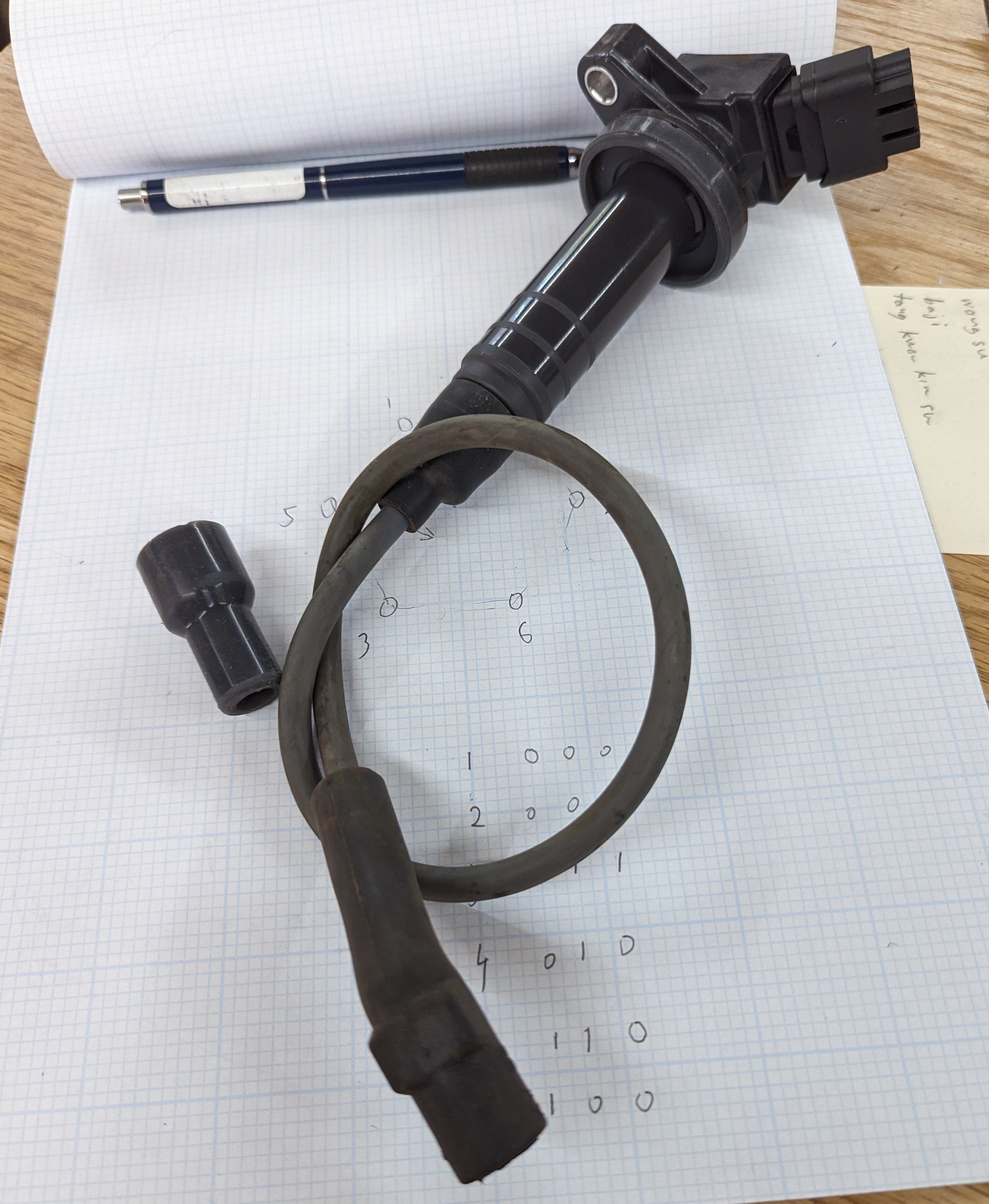

OK I rummaged around in search engine and RockAuto.com and found some cheap, common Toyota coil on plug modules for which I can get connectors too. And bought one. The issue is (see photos) this is an old pushrod OHV motor, cam in block, and all COPs are designed to fit down through the valve cover etc. So it dangles. This is a really small car, and even if I make brackets to support them, it’s bust. I’m not relocating the battery (umm low center of gravity was not ever considered…) so this scheme won’t work.

I think coil-near-plug as a smart Volvo fan suggested is the next thing to look at; I’d ordered this part before that post. I’ll post on that when I find one to examine.

In the mean time here are photos of failure, lol. Projects like this are failure every step of the way through success.

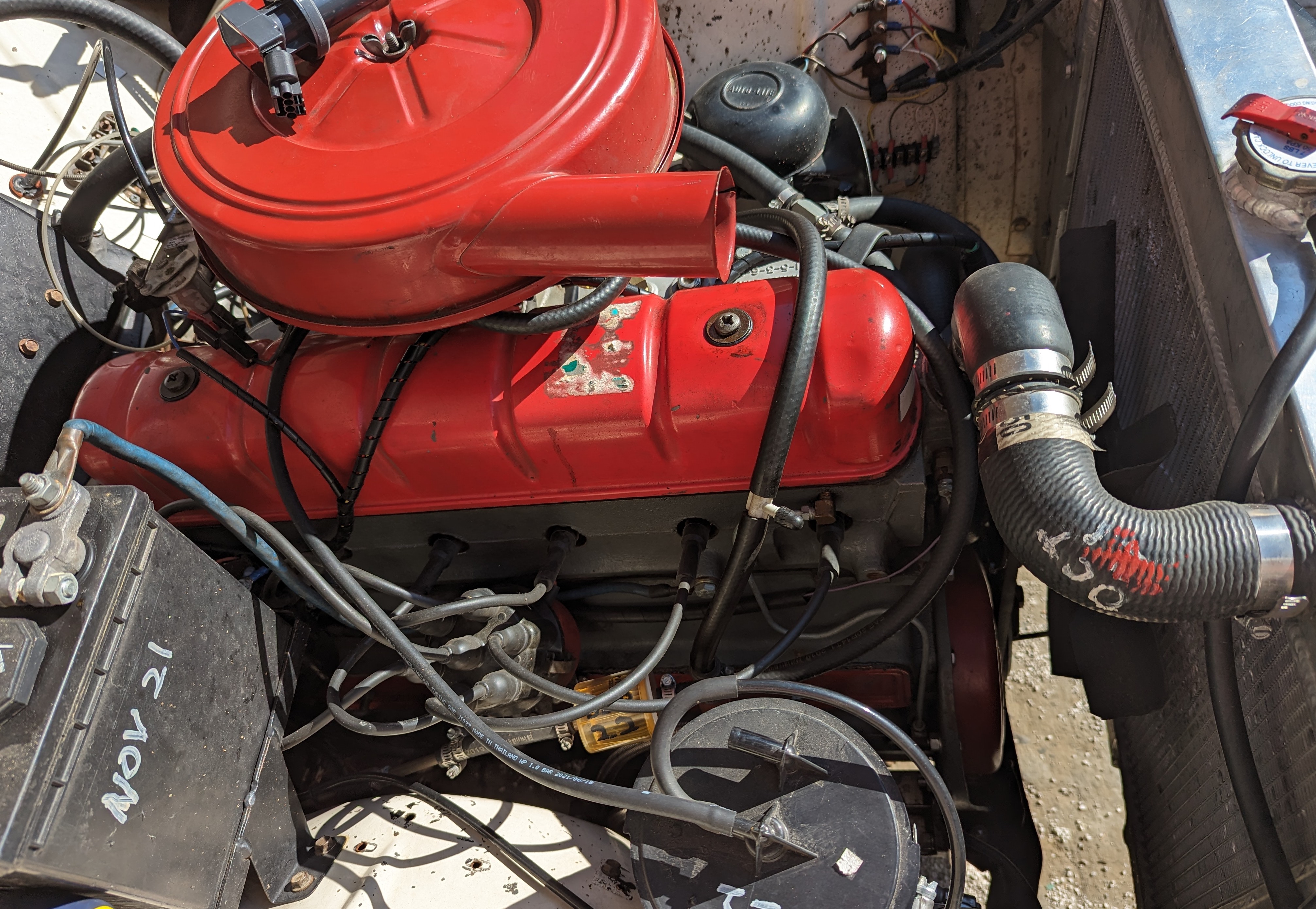

Plug side of the motor. It’s a very small car, same wheelbase as a Yaris (within 5mm). Tiny engine compartment especially for 1960.

COP on plug #2. Immediately obvious to me not gonna work. Simply too tall. Cyls 1, 2, 3 maybe, but 4, 5, 6 are under the battery and I’m not moving that (again). Too cluttery.

Lifted by hand to in-line with the plug.

Here’s the module itself. Lovely thing! Coil and MOSFET driver right in the sealed unit. I lurv this new shit.

Why not just use something like the MSD conversion COP setup? Basically you remote mount the coils and then make wires to the correct length. Iirc the kit even has then ignition control box and distributor

Also, not sure about Toyota but on most Nissans I’ve seen, with coil on plug, the boots come off, so you could theoretically do the same thing as the MSD with the coil packs you have if you remove the boots and then remote mount.

I’d rather not use Holley/MSD stuff. It’s aimed at the high-horsepower, GM V8 scene, grossly oversized for my 125 hp engine. I find Holley’s tech not all that well made, and definitely not OEM quality (though OEM quality is highly variable… and aftermarket replacement parts can be sketchy). Those are $100 per coil, and I need six. The stuff is physically huge. And if one fails, they have to be ordered from Holley or Summit or something. I’m making 20 hp/cylinder and it can’t possibly rev past 4500 rpm.

The last part will get me flamed but tough shit: Holley’s support forum for their EFI is admin’ed by a guy I had to battle to even sign up to. Bible quotes on every reply. Shitty and officious and incorrect technical advice.

But it’s also more interesting to work out properly-scaled OEM stuff I can adapt from junkyard sources.

I will go look at Nissan too, thanks for the hint! A coil-near setup will be tolerant of some lead length too, I kinda don’t want to “research” subtle coil behaviours that result in failure “later”!

Fair. I hate holly too.

Look specifically at the B15 Sentra (QR25DE engine)coil packs. With the boot off there is maybe an inch/inch and a half protruding from the bottom IIRC. That would be 2002-2006 iirc.

This one? https://www.rockauto.com/en/moreinfo.php?pk=2417170&cc=1429589&pt=7060&jsn=386

Here’s the NGK part: https://www.rockauto.com/en/moreinfo.php?pk=9165460&cc=1429589&pt=7060&jsn=398

Does that long neck come off? Or is that the wrong part?

QR25DE

Yeah the whole boot comes off and there’s a little plastic protrusion. Let me see if I can find a pic.

Idk what that NGK part is for, but not a b15.

Not the first rockAuto error I’ve found.

Oooh thanks! Will look em up when I get home!!

I can’t find a good picture of them but this is the dealership parts departments image to search from.

If you look at the pic you posted, the boot comes off at the flared rubber part. Inside there’s a spring, which makes the connection from the coil pack body to the end of the boot. The part that sticks out of the bottom on the coil pack is just enough for the boot to snap over. Idk if it’ll be exactly what you’re looking for, but that’s one of the more low profile I’ve seen (not overall, just on the “business end”.

The boot and spring looks like this loose

YES! Thanks!! Wow, the devil’s in the details… They “all look like that” but on the few I’ve seen, the long snout is cast plastic and not removable. That makes a huge difference. Thanks so much for the detail!

Gonna get to an LKQ (junkyard) next week and try to find one for a look-see. Nothing like having a thing in your grubby hands for gathering information.

Seriously, I can’t thank you enough. This is great info.

You’ll probably be hard pressed to find a B15 Sentra with a QR25 in it. It was only available in the SER and Spec V. BUT the 4 cylinder Altima (iirc 2001-2006) SHOULD have the same coil pack (same engine, different tune)

Failing that, look at LS1 coils.

And no problem. I literally do what you’re doing for a living. Mostly.

Also on RockAuto there’s a separate replacement part for “spark plug boot” – which seems to be exactly your removable part, so that gives me more clarity. This search shows it… https://www.rockauto.com/en/catalog/nissan,2006,sentra,2.5l+l4,1432234,ignition,spark+plug+/+ignition+coil+boot,10150

HA! Never do what you’re told. I like the COP modules for their integral driver. Saves a lot of design and power issue transporting spark coil power around…

So I yanked the rubber boot off the end of the toyota COP module… aaaaand it turns out that it’s shape is nearly identical to a distributor cap tower socket. Aaaaaand a regular spark plug wire fits it. Instant coil near plug…

Now I know these things are designed with very thin margins… and I’m not sure if the module will tolerate the added cable (inductance and resistance). So at the least I’ll set one up on the bench with a “long” plug wire and run it for a few thousand cycles and see if it bursts into flames or something. (likely death will be a hole punched in a silicon barrier and… silent death).

20 bucks each and driver built in and available at autozone on the road…

Welp, things change.

I’m likely not gonna continue with this project, now anyway, for the simple reason that putting electronics inside a distributor, even if it’s as little as IR sensors and LEDs, is too unreliable. (Pertronix modules have a tiny micro in them, and are quite reliable, so maybe I’m being too conservative here. But is it commercial temperature range stuff? No idea.)

It’s easily 200F/95C in there, inserted into an engine block at 195F/90C+ operating temperature. Low reliability is the LAST thing I want.

The overriding reason for a modern ignition system was to get control over spark timing (advance) so that I could take advantage of the leaner mixtures I can controllably get with the electronic carburetor. Not necessarily a lot more advance, just control over it.

For the short term I’ve switched to a different distributor I’ve had for sometime, an old contact-points distributor someone hacked to take a Ford Duraspark type variable reluctor driving a GM HEI module. They did a poor job mounting the coil square to the moving pole, so I spent a day (aargh) fixing the bent “points” plate and got the gap to be a solid .015" and square. It was angled, < .010 at the top and .020 at the bottom and spark was a bit erratic. Seems solid now, when it cools off I’ll put the oscilloscope on it and see how much it jumps around.

The engine turns so slow (RARELY does it spin even 3000 rpm) that a dumb old single coil is adequate.

I cobbled up code for a distributor with optical position sensor, but given how much of an overall PITA distributors are I’m at this point more likely to scrounge up some EDIS-6 stuff and bolt a wheel to the harmonic balancer, even though that gear is from the 1980s.